Share to

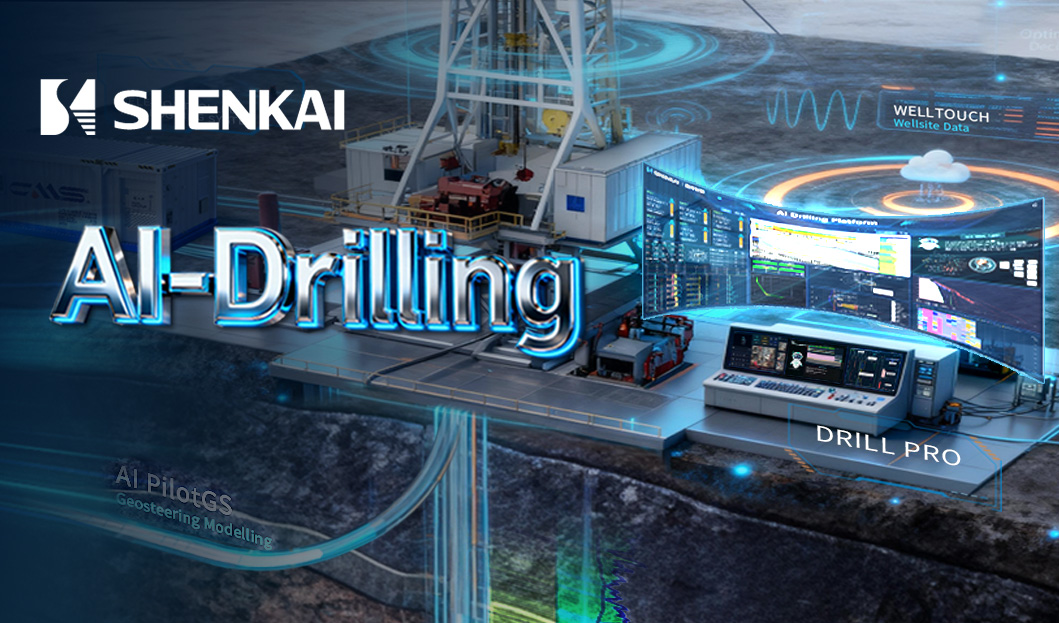

Recently, at the world-renowned energy industry event — Abu Dhabi International Petroleum Exhibition and Conference 2025 (ADIPEC 2025) — Shenkai BOET unveiled its independently developed AI-Drilling Cloud Platform System. As an innovative achievement integrating cutting-edge artificial intelligence technology with oil and gas engineering practices, the platform immediately attracted extensive attention from international clients, industry experts, and partners upon its debut, creating a vibrant atmosphere at the exhibition. BOET was also invited to participate in several technical forums, where it engaged in in-depth discussions with Aramco, KOC, and ADNOC on accelerating the oil and gas industry’s transition toward AI-driven transformation, fully demonstrating Shenkai’s technological strength and forward-looking vision in the global energy intelligence revolution.

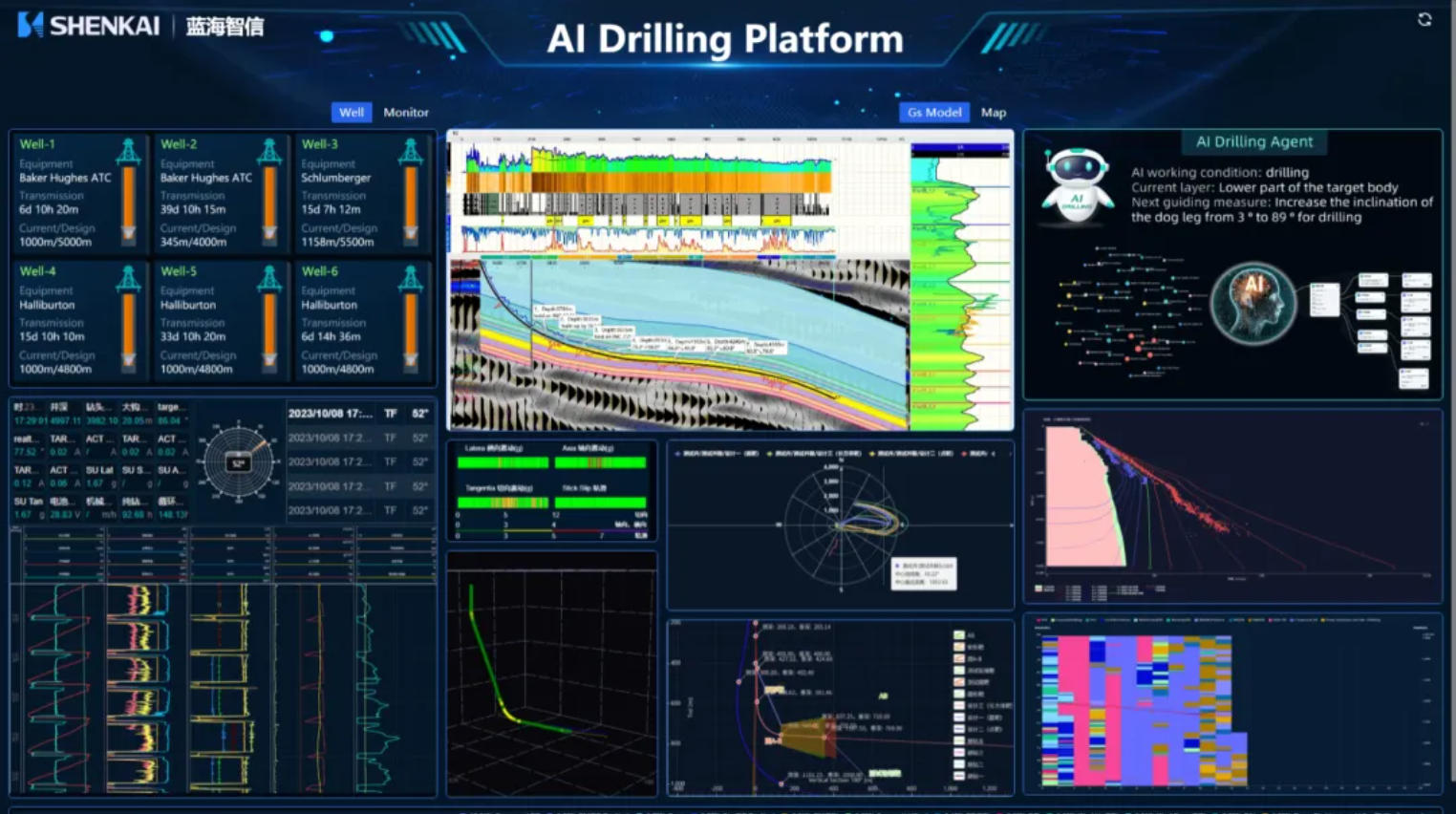

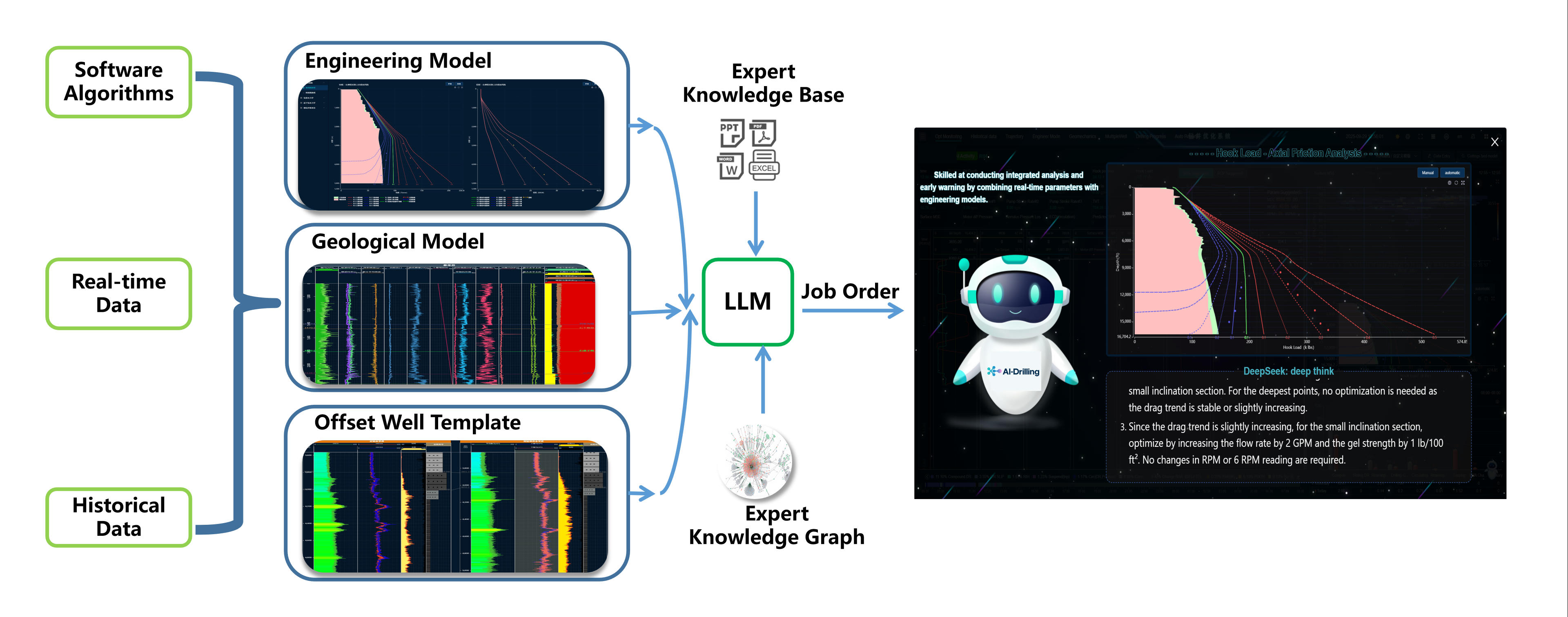

The AI-Drilling Cloud Platform System is an intelligent drilling decision-making platform that deeply integrates Large Language Models (LLMs) with a Multi-Agent System (MAS) collaborative architecture. By fusing real-time multi-source heterogeneous data—including drilling site engineering data, Measurement While Drilling (MWD), mud logging data, and geological modeling—the platform enables multiple specialized AI agents to work collaboratively in parallel. This empowers dynamic parameter computation, intelligent analysis, and autonomous optimization of the drilling process, significantly enhancing drilling efficiency, safety, and reservoir encounter rates.

AI-Drilling Cloud Platform System

Four Core Intelligent Agents — The “Smart Engine” of Drilling Operations

1. Drilling Optimization Agent

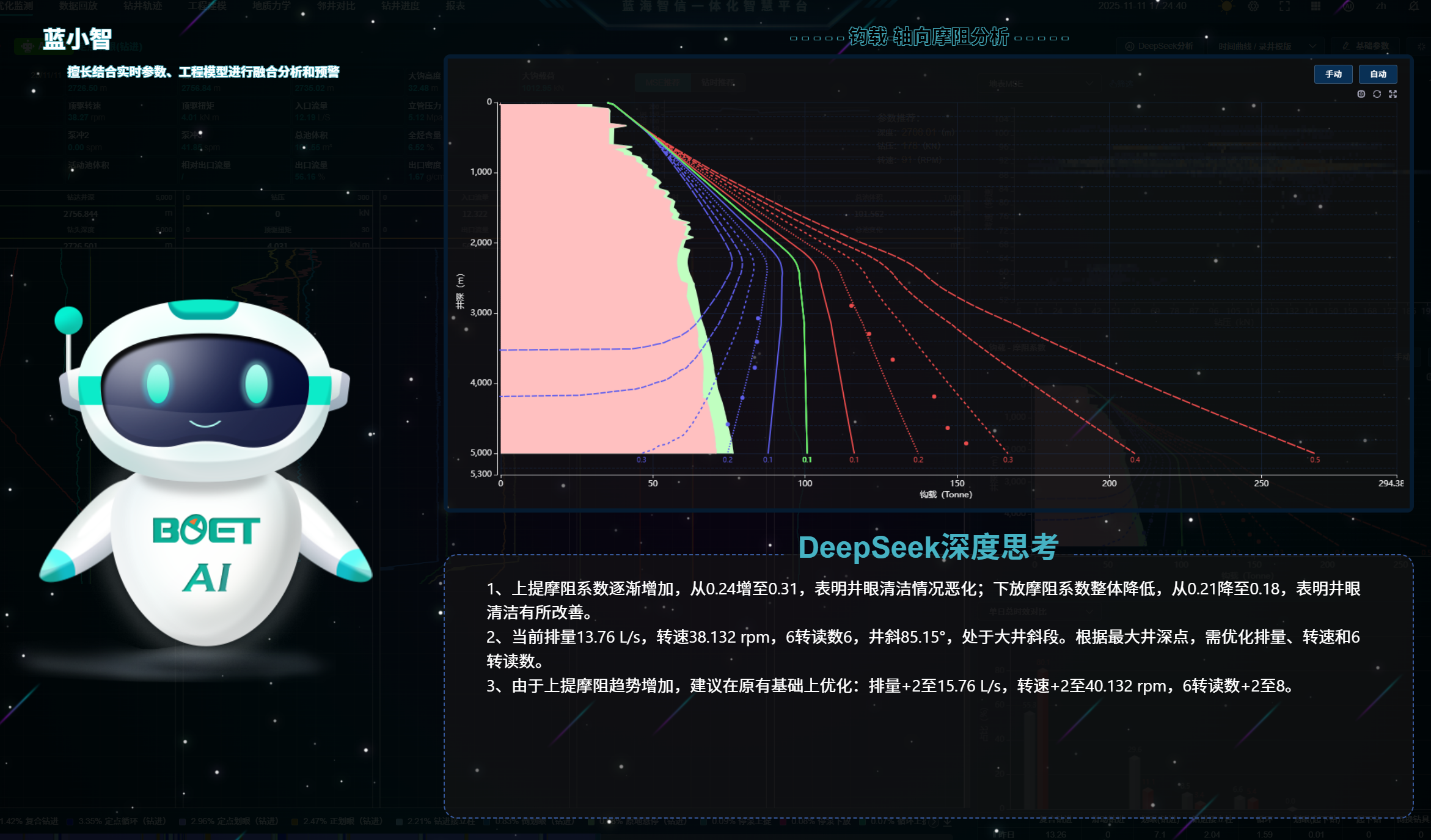

The Drilling Optimization Agent functions like a “human expert”, possessing autonomous perception, analysis, and action capabilities. It conducts collaborative decision-making by integrating three categories of key information: it is driven by real-time data, supported by industry models such as torque and drag simulations, and guided by embedded domain knowledge.At its core, the agent is able to detect discrepancies between real-time data and model predictions, invoke an expert rule base for reasoning, accurately diagnose the root causes of complex operational conditions, and generate reliable decision plans.

At the technical level, its intelligence is derived from a multi-layered closed-loop architecture. Through the WITSML standard protocol, the system ingests and cleans multi-source data in real time. Physical models are then used to compute key derived parameters—such as Mechanical Specific Energy (MSE), Equivalent Circulating Density (ECD), and cuttings slip velocity—forming the foundation for subsequent analysis.

The simulation layer builds engineering parameter prediction models based on real-time trajectory, bottom-hole assembly configuration, wellbore structure, and drilling fluid properties. This enables accurate prediction of parameter trends and establishes a benchmark for anomaly detection.

The cognitive and decision-making layer serves as the system’s core. When the trend of real-time data deviates from model-predicted trends, the system automatically triggers specialized analytical agents. The embedded expert rule base performs inference and completes anomaly diagnosis. The agent then retrieves predefined solutions or dynamically generates optimal decisions through optimization algorithms (e.g., adjusting weight on bit or rotary speed), while evaluating the associated risks and expected outcomes. Finally, the system presents the diagnosis and optimization plan to engineers, or autonomously executes fine-tuning of parameters. Through continuous learning within a closed loop, it evolves its decision-making capabilities, achieving autonomous optimization and safe control throughout the drilling process.

Drilling Optimization Agent

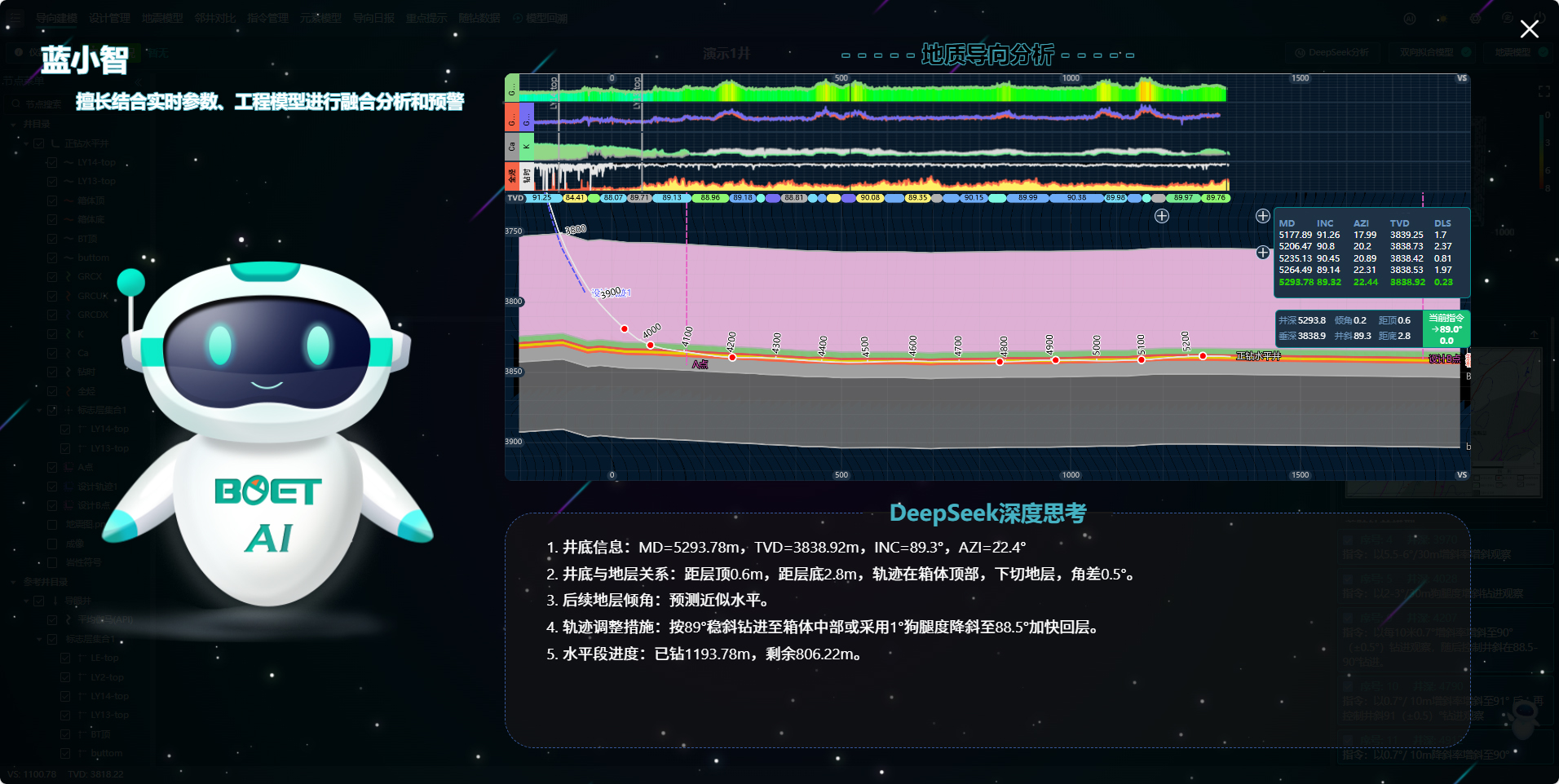

2. Geological Steering Agent

The Geological Steering Agent focuses on precisely navigating the drill bit trajectory. By leveraging real-time gamma/resistivity logging-while-drilling data and dynamically constructing geological models through TVT bidirectional fitting, the agent applies advanced reasoning methods and uncertainty quantification techniques to analyze reservoir boundaries and determine the exact position of the drill bit. Based on this analysis, it automatically identifies the optimal target landing point and, combined with advanced trajectory planning algorithms, proposes an optimal drilling path. This process not only enhances steering efficiency but also ensures the safety and economic performance of drilling operations.

At the technical level, the agent first acquires high-quality real-time LWD data through standardized protocols, then conducts in-depth analysis of the geological model. By evaluating the spatial relationship between the drill bit and the reservoir, and using an embedded expert rule base along with algorithmic tools, it plans the optimal next-step drilling trajectory, formulates corresponding adjustment strategies, and generates trajectory optimization recommendations.

Geological Steering Agent

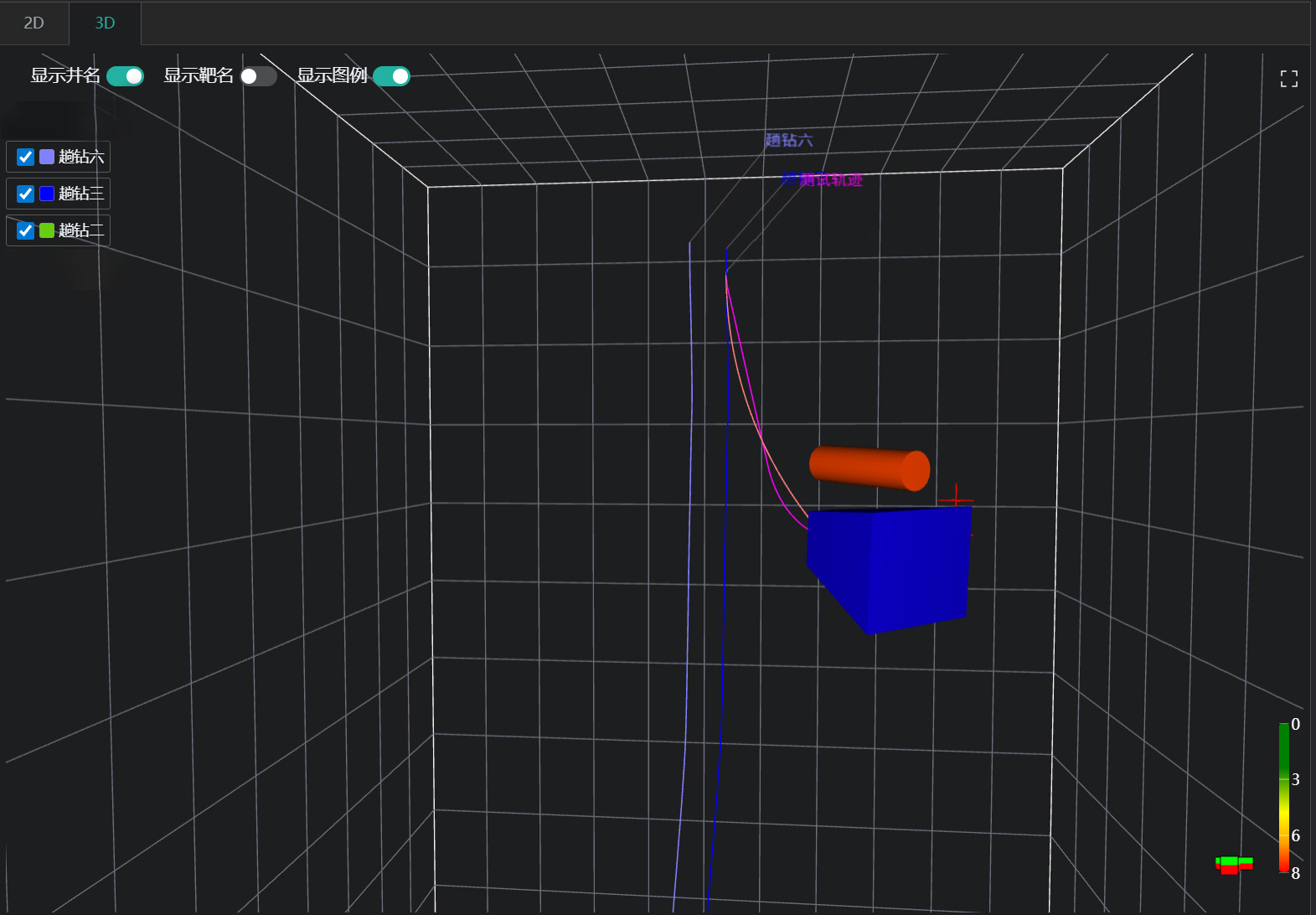

3. Directional Well Design Agent

The Directional Well Design Agent is an automated design tool capable of rapidly and efficiently generating three-dimensional drilling trajectories that meet specific engineering requirements. Upon receiving path constraints and target-point instructions from the Geological Steering Agent, or user-defined design requirements, the agent invokes trajectory-generation algorithms and automatically inputs all necessary design parameters to produce a 3D planned trajectory that satisfies dogleg severity (DLS) constraints. A design process that traditionally required tens of minutes can now be completed within seconds.

At the technical level, the agent first parses instructions from the Geological Steering Agent or user-defined inputs to fully understand the design requirements and constraints. It then applies high-efficiency trajectory design algorithms to quickly generate drilling trajectories that meet all requirements, significantly reducing the design cycle.

Directional Well Design Agent

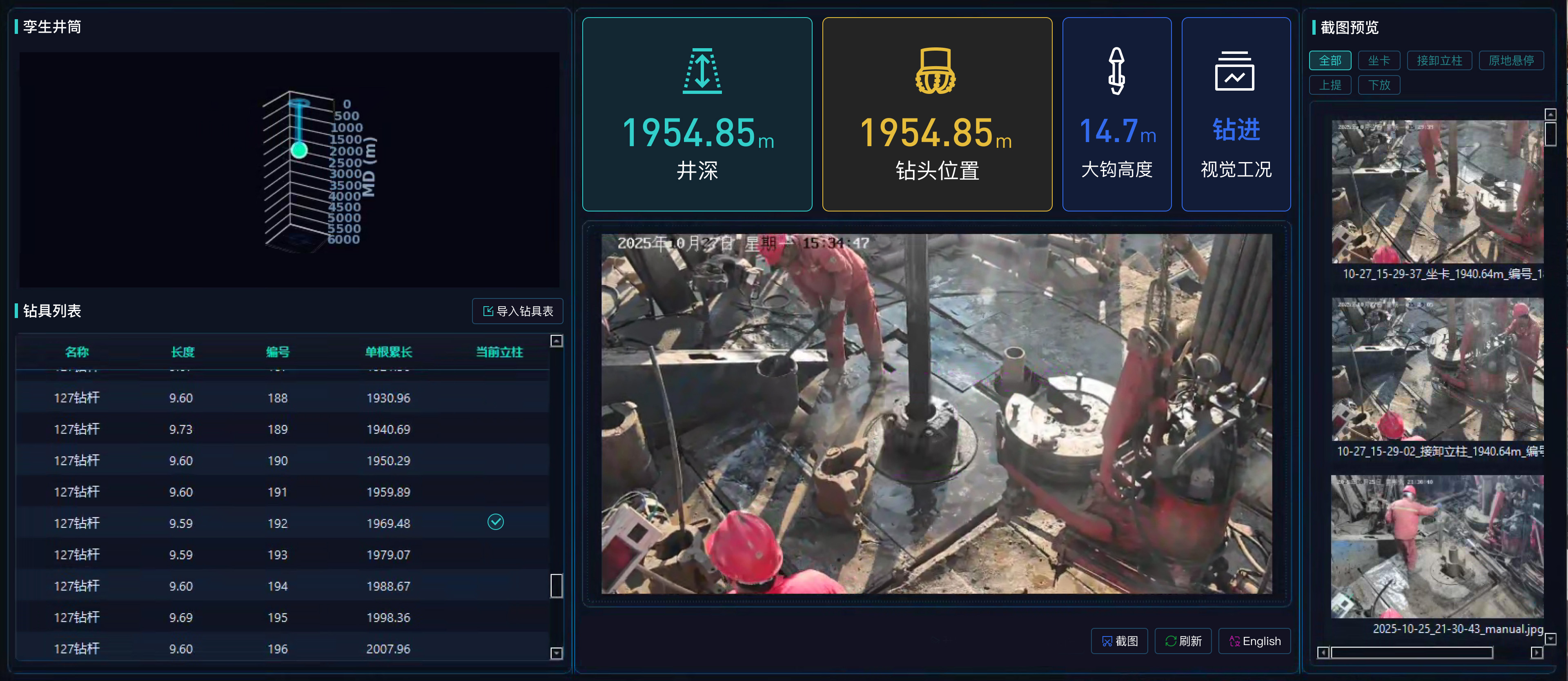

4. Visual Operations and Depth-Tracking Agent

The Visual Operations and Depth-Tracking Agent is an advanced monitoring solution equipped with a multimodal vision foundation model capable of performing real-time recognition of drilling-floor operational states—such as making a connection, tripping in/out, and stuck-pipe situations—based on rig-floor video streams. By integrating Bottom-Hole Assembly (BHA) metadata with multi-source sensors, the system achieves sub-meter depth-tracking accuracy, effectively compensating for data blind spots caused by threshold delays or failures in traditional sensors. Even in scenarios without available sensors, the agent can provide reliable monitoring results through a dual-verification mechanism combining “vision + logic,” offering users a cost-effective and highly efficient visual monitoring solution.

Visual Operations and Depth-Tracking Agent

AI Customization Solutions:

From Standardized Products to Personalized Intelligent Partners

As standardized AI products often fall short of the complex demands of industrial scenarios, Shenkai BOET has introduced a deep-customization service for AI Agents tailored to the oil and gas industry—going beyond functional adaptation to build intelligent agent systems deeply integrated with an enterprise’s business logic, knowledge assets, and decision-making workflows.

Construction of Private Knowledge Bases: Historical reports, expert experience, and incident cases are structured and injected into the platform. Through semantic parsing and entity-relationship extraction, they are transformed into a structured knowledge graph for the oil and gas domain, which is embedded into the agent’s reasoning engine. As a result, the AI can not only answer generic questions but also make context-appropriate judgments based on domain-specific understanding.

Custom Model Development and Fine-Tuning: Leveraging efficient parameter-tuning techniques (such as LoRA and SFT), industry-specific prior knowledge is infused into advanced base models like Llama and Qwen, producing domain-specialized large models that support on-premises deployment to ensure data sovereignty. These models also possess continual-learning capabilities, enabling them to evolve alongside business needs.

Multi-Agent Orchestration Engine: Built on a modular and microservice-oriented architecture, the platform provides a visual orchestration environment for intelligent agents. Users can freely define trigger conditions, information-exchange pathways, and collaboration logic among multiple agents according to real-world business workflows.

Agent Application Example

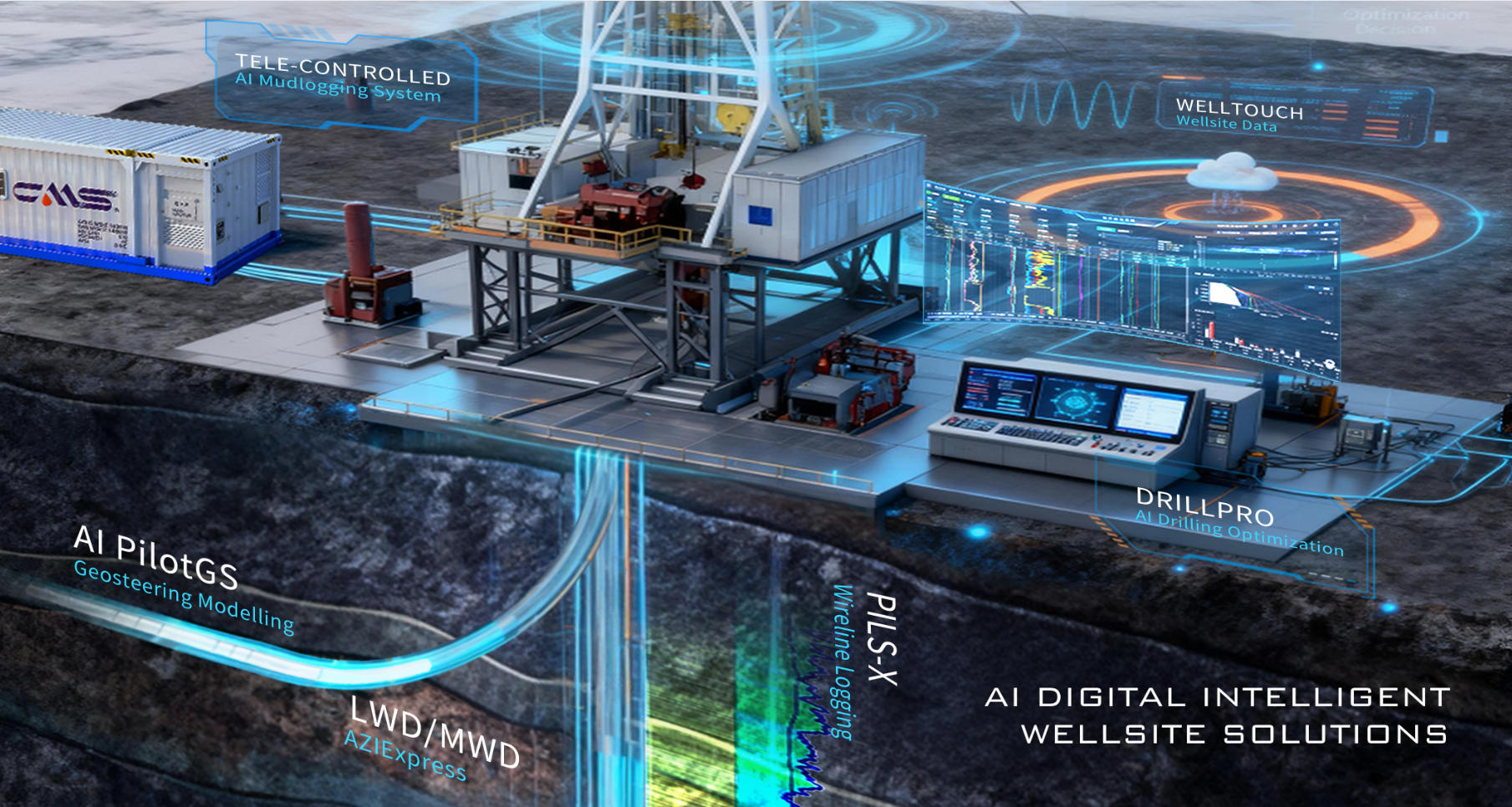

As the global energy industry accelerates its transformation, Shenkai has formulated a four-stage digitalization roadmap—Remote Logging → Integrated Survey-Measurement-Logging → AI-Assisted Decision-Making → Intelligent Wellsites. The successful debut of the AI-Drilling Cloud Platform System overseas marks a significant milestone in Shenkai’s deep integration of artificial intelligence with traditional oil and gas operations, demonstrating the company’s determination and capability to advance global drilling operations toward automation, intelligence, and greener development.

Looking ahead, Shenkai will uphold its development philosophy of helping customers “acquire energy safely, efficiently, and sustainably.” The company will continue to increase R&D investment in the AI + Energy domain and, together with global partners, jointly build a more efficient, safer, and more sustainable ecosystem for future energy development.